Our Services

Toolmaking Plastic Injection Moulding TurnKey Solution

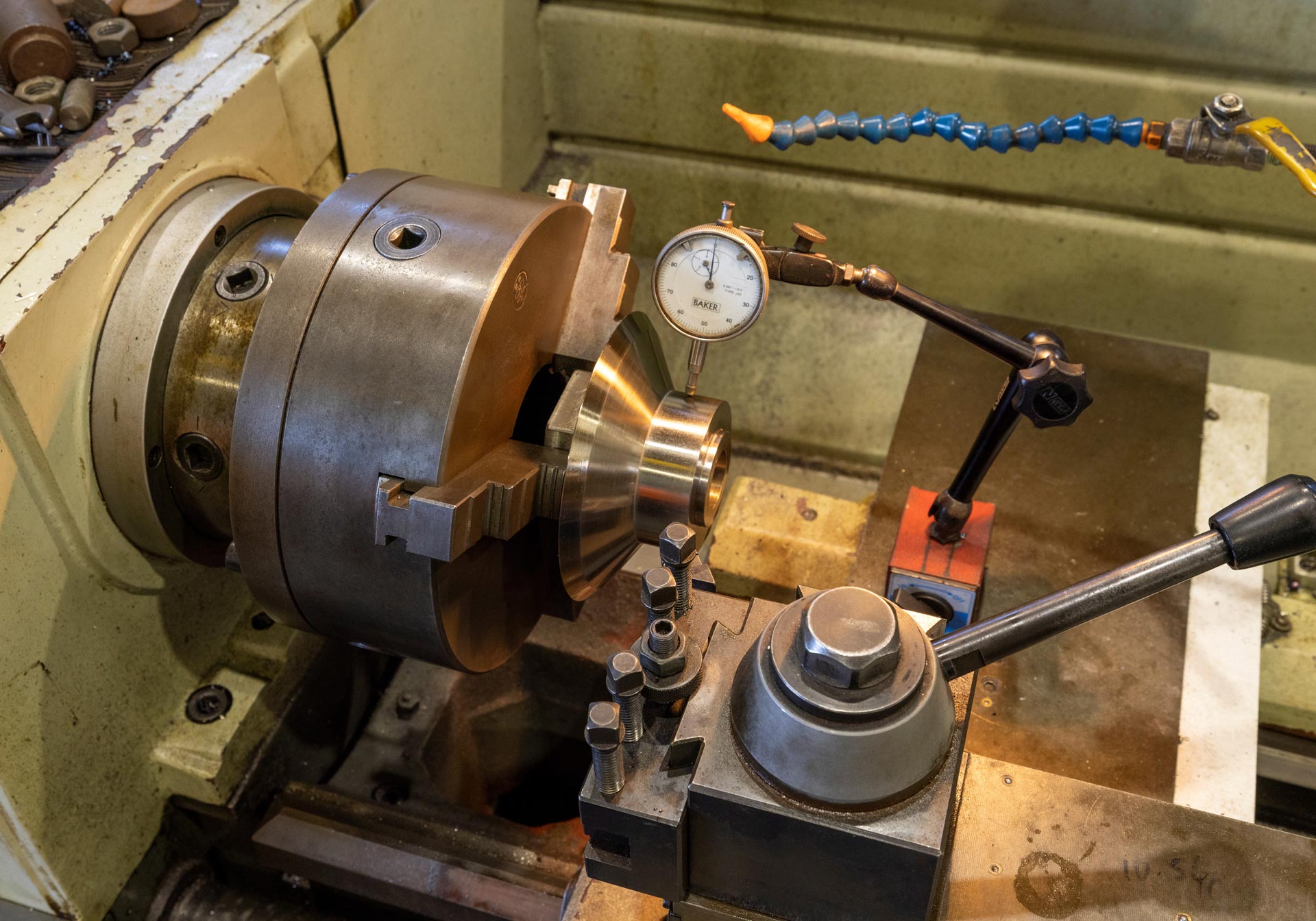

We offer a precise tool making management service that has us overseeing tooling projects in China. This service allows us to deliver moulds that are low in cost, yet made to Australian standards. Our years of experience allow us to help our clients to develop a better quality mould than may be obtained by them dealing with China directly. Contact us today to see how we can help guide you in the production of your mould.

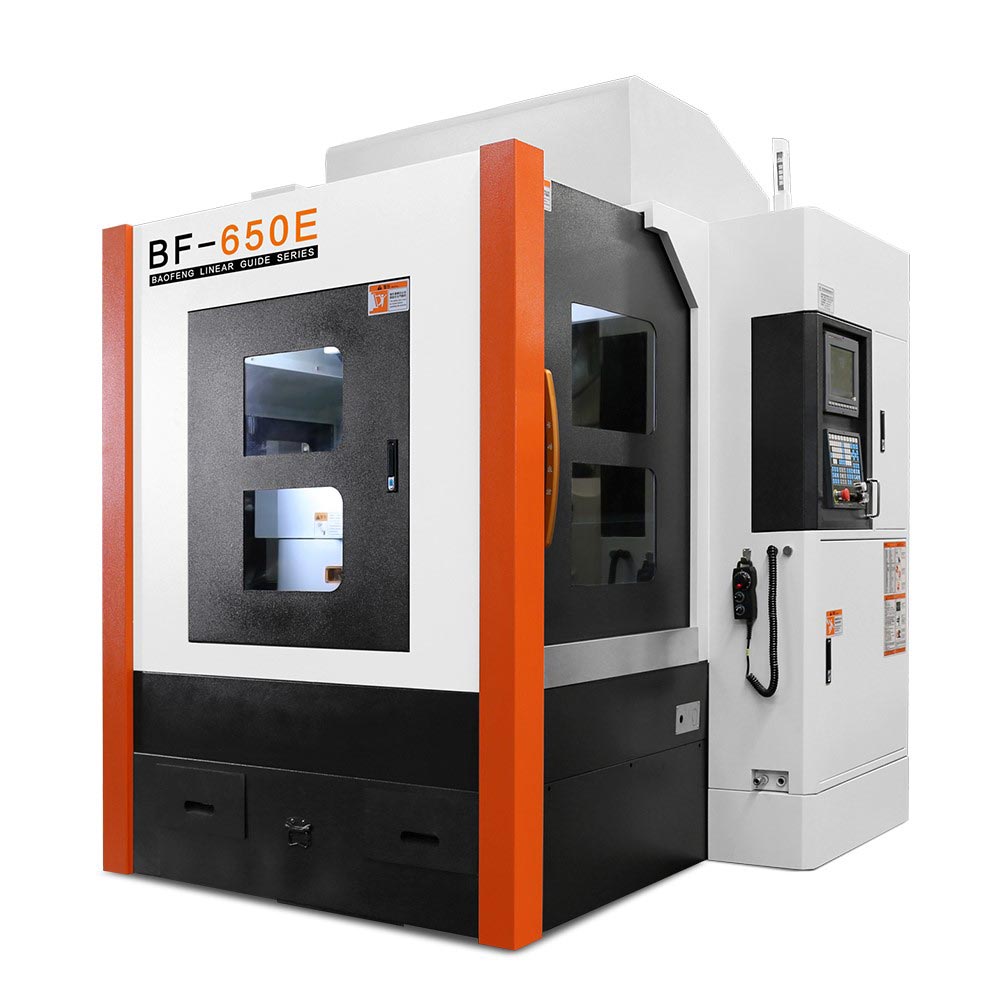

With injection moulding machines ranging from 490t down to 25t hydraulic presses, we can mould a full range of plastic products across all industries and applications. We maintain competitive prices and quality assurance procedures that have seen us produce parts for high end gaming machines and for the automotive market. Contact us today to see how we can help to improve the quality, price and turnaround time for your product range.

At Deeps Engineering, we take pride in ensuring we have state-of-the-art plastic injection moulding and CNC equipment that allows us to deliver top-quality plastic components manufactured to our customers' exact specifications.

Our 3D printing capabilities allows you to test the fit and function of your concept without the capital investment of a production injection mould. We can produce printed prototypes in a wide range of engineering polymers. Get in touch today to see how we can help.

Vacuum Forming

Vacuum Forming Newcastle

Plastic Injection Moulding Newcastle

Plastic Injection Moulding

Injection Moulding Newcastle

Injection Moulding

Our Vacuum forming department is available for any of your packaging requirements. Specialising in PET and PVC Blister packaging our team can assist in the right solution. Get in touch today to see how we can help.

Our complete package services can help you with a new product from the design phase, through the tooling and moulding process and right up to completed and assembled end use products. We will be with you every step of the way, helping to make your idea or product a reality without breaking your budget. Contact us today to see how we can help bring your ideas to life.

CAD Design and Prototyping

Whether you have a concept, a 2D sketch or a 3D CAD file our team has the capabilities to help you take your vision to the next step. Utilising the latest CAD and CAM software Deeps Engineering can bring your concept life. Get in touch today to see how we can help.

Sustainable Solutions at Deeps Engineering: Redefining Waste, One Grind at a Time. Committed to reducing our environmental footprint, we aim to cut our internal waste by up to 80%.

With our state-of-the-art grinder, we transform plastic waste into a valuable resource, recycling materials like Polypropylene, Acrylic, HDPE, ABS, and Corflute.

Partnering with Hunter New England Health, we're removing rigid plastics from their waste stream.

Join us in the journey towards a cleaner future, where recycling capabilities meet environmental responsibilities.

Get in Touch

Contact Us

We will get back to you as soon as possible.

Please try again later.